ThermaTech Modular, superheated-water cleaning equipment

Download our brochures

Technical Guide: download our Technical Guide for the ThermaTech Superheated Water-based Masonry Cleaning System for an overview of the product. We explain how the ThermaTech works, offer a description and full technical specification, and advise on how best to clean certain coatings.

Information Brochure: download our ThermaTech Information Brochure for further details on the ThermaTech system. This includes an introduction to the full range including the Standard and INOX models, case studies showing before and after images, customer testimonials, and details of how best to get in touch if you would like to know how we can help you.

Where has it been used?

"The ThermaTech was the perfect machine for this job, it removed the old limewash without disturbing the underlying historic render and masonry"

Philip Scorer

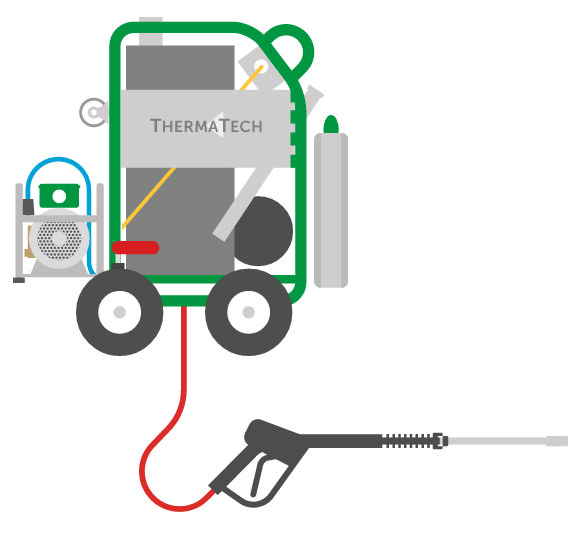

A modular approach to design

ThermaTech is a modular system designed for safety, usability and ease of transit. Some elements are removable to facilitate use, storage and compact transportation.

Pump

Triggers / lances

Frame

Jerrycan

Friendlier to the Environment

ThermaTech has been specifically designed for reliability using high quality, recyclable materials, reducing reliance on chemicals and boosting the performance of milder agents.