ThermaTech® Inox

Where has it been used?

My father always taught me that you need the right tool for the job. He would say, “When you have the right tool, the job will get done faster, and it will be done proper.” I couldn’t agree with him more when talking about Restorative Techniques INOX on cleaning historical masonry. It is the right tool for the job.

Lee LabasLabas Construction

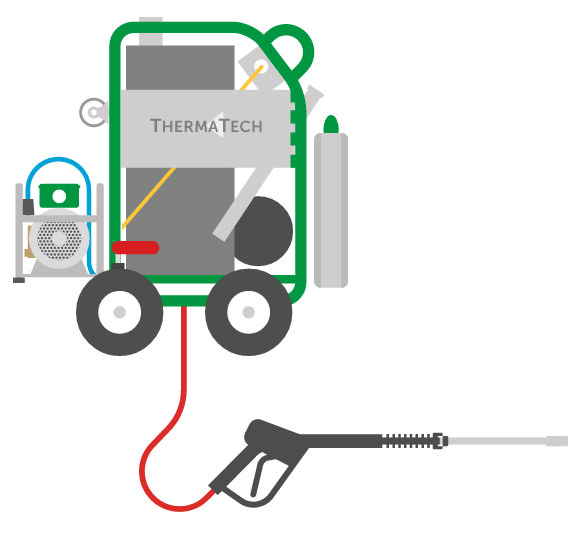

A modular approach to design

INOX is a modular system designed for safety, usability and ease of transit, at the same time as meeting a demand for exceptionally high performance, making it particularly well-suited to paint removal and large-scale cleaning.

Pump

Triggers / lances

Frame

Jerrycan

Friendlier to the Environment

ThermaTech has been specifically designed for reliability using high quality, recyclable materials, reducing reliance on chemicals and boosting the performance of milder agents.

User Friendly Design

Key Technical Details

THERMATECH® INOX ELECTRIC PUMP MODEL

The ThermaTech® INOX, Electric Pump system is supplied with the following:

- 1 x ThermaTech® INOX Boiler*

- 1 x ThermaTech® 110v/230v INOX Electric Pump (Electric Pump unit, to hang onto main module)**

- 1 x 20 Litre Stainless Steel Silver Jerrycan

- 1 x 20 Metre High-Pressure, Super-heated-Rated, Twin-wired Water Hose (red)

- 1 x Gun / Trigger

- 2 x Lances; 1 Short Lance Fitted with HP Nozzle & 1 Long Lance Fitted with HP Nozzle

- 1 x 25 Metre IP67 Electric

- 5 Litre Descaler

* (main module on the 4 wheels) & Drop-in Transformer 110v/230v - 24v fitted (inside stainless side panel)

** Type of voltage dependent on choice of pump, i.e.; 1 x 25 Metre IP67 Electric Cable, Yellow, 6mm² for 110v OR, 1 x 25 Metre IP67 Electric Cable, Blue, 4mm² for 230v.

THERMATECH® DIESEL-POWERED PUMP / GENERATOR

The ThermaTech® diesel-powered pump / generator is a complete innovation in the restoration field. Invented and developed by Restorative Techniques, it has been designed with reliability and performance in mind, without the need for compromise with regards to size and weight. The revolutionary design and features of this unit are protected by a new patent (the second patent granted to the ThermaTech® range of equipment).

The compact diesel engine drives the pump direct, which cuts out the reliance on a vee belt driving a high powered pump. The engine also drives a generator to provide more than 500 watts of power for the boiler from a 16A socket.

When combined with the new INOX model of ThermaTech® boiler, the system will run at an incredible 170 bar, 9.5 litres per minute, with the power to still continuously maintain 150°C. This performance capability means that the system is able to function at the same level of efficiency.

THERMATECH® INOX DIESEL GENERATOR & PUMP MODEL - WITH ELECTRIC START & PULL CORD

- 1 x ThermaTech® INOX Boiler (main module on the 4 wheels)

- 1 x ThermaTech® INOX Compact Power Unit, Electric Start - Combined Pump / Generator Unit

- 1 x 20 Litre Stainless Steel Silver Jerrycan

- 1 x 20 Metre High Pressure, Super-heated Rated, Twin Wired, Water Hose (red)

- 1 x 10 Metre High Pressure, Super-heated Rated, Twin Wired, Water Hose (red)

- 1 x Gun / Trigger

- 2 x Lances; 1 Short Lance Fitted with HP Nozzle & 1 Long Lance Fitted with HP Nozzle

- 5 Litre Descaler

* Diesel-powered pump / generator module, to hang onto main module and power complete system. (For when off-grid).

ADVANTAGES OVER ELECTRIC PUMP RUNNING ON GENERATOR:

- Just one unit for water and electricity

- No petrol needed, as the system runs completely on diesel

- There’s a large weight saving, as there is no longer a need for combining a 5kva generator and electric pump

- Up to 170 bar working pressure at 9.5 litres per minute (electric 140 bar @ 9 litres per minute)

- Extremely compact! It can hang on boiler or be placed on floor as own unit. A wheel kit is also available for portability

- Low volt outputs for spotlighting or for the charging of personal equipment such as cameras, phones etc

- Less than 1 litre per hour fuel consumption, even at maximum output