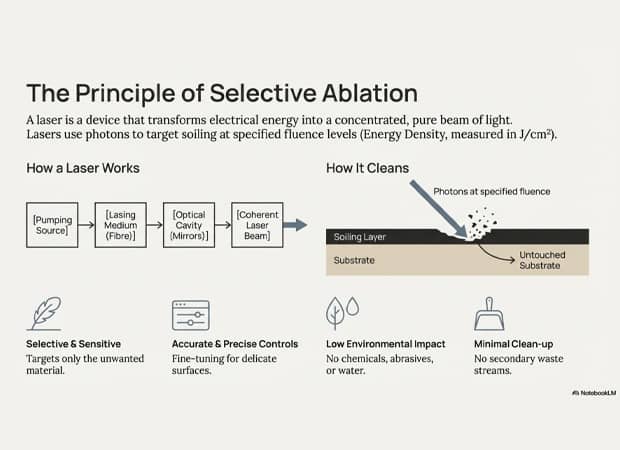

How It Works

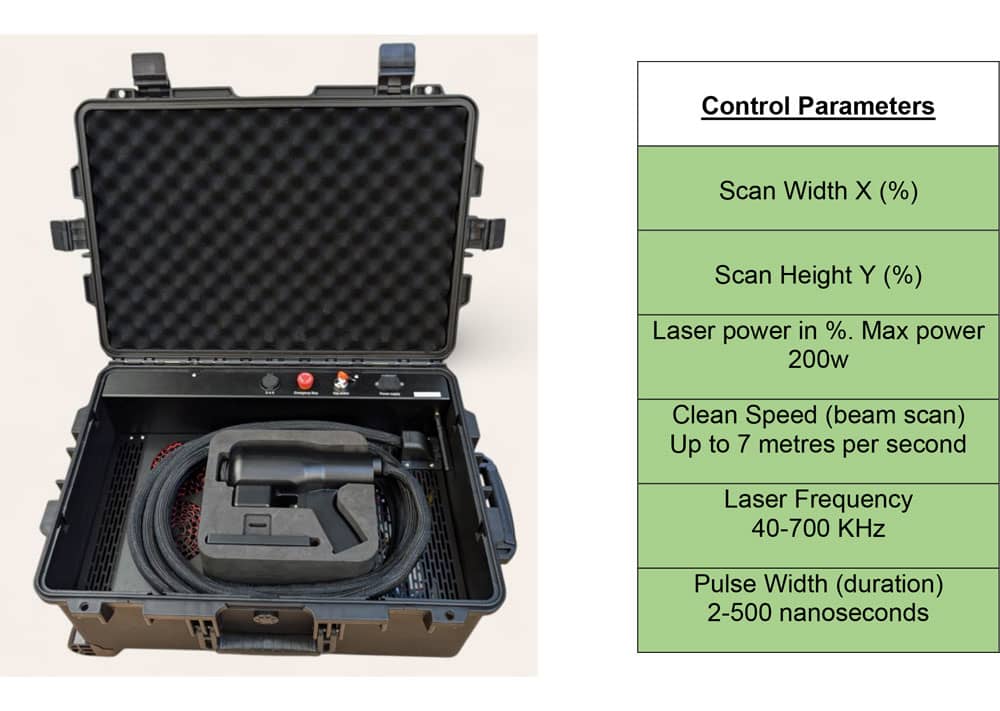

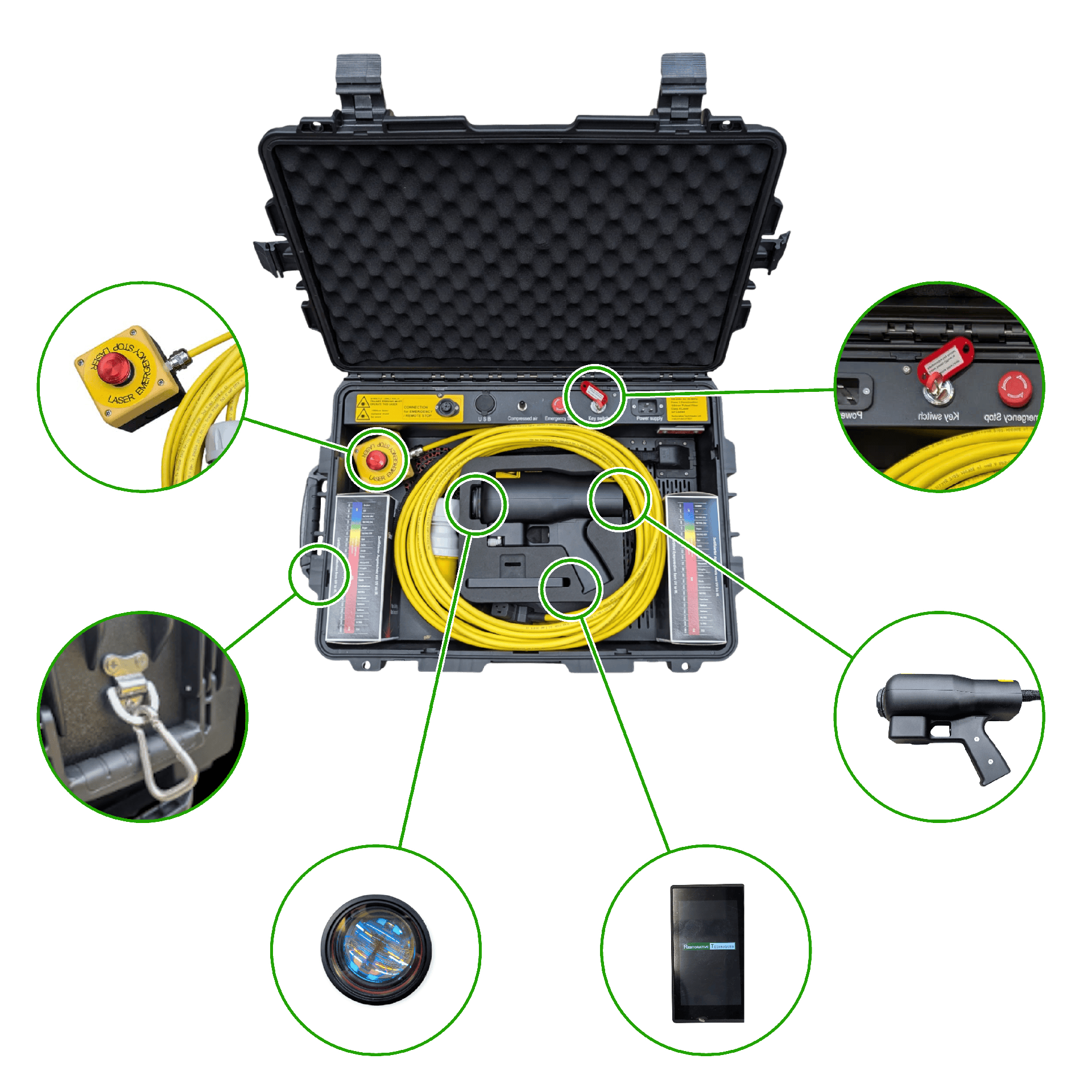

Lasers use photons (the subatomic fundamental particles that convey light) to target soiling at specified fluence levels (a measure of energy density, expressed in joules per square centimetre).The laser beam emerges through a handpiece, which is held by the operator. Lenses within the handpiece allow for the focusing of the laser beam and control of the energy density at the surface. The laser incorporates an aiming beam (a low-power, continuous, visible laser beam), which itself allows careful targeting of the actual cleaning beam.